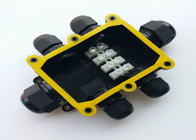

Automotive Plastic Parts Injection Molding Using 20% Glass Reinforced PC Resins

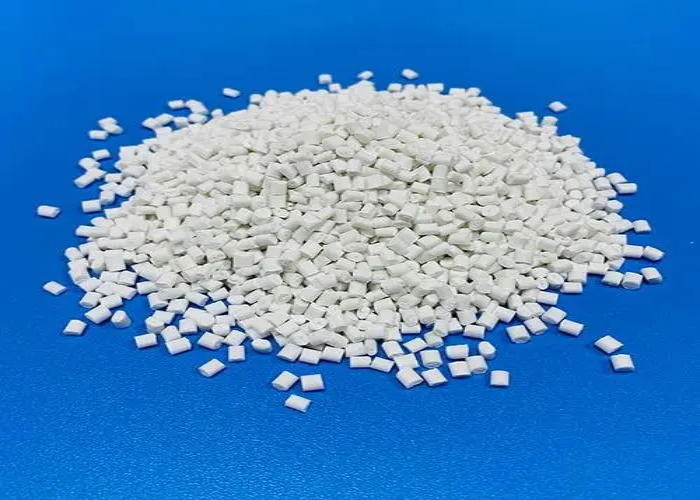

Polycarbonate resin, known as PC in industry, is widey most used in making automotive parts by injection molding because of its outstanding physical performance, especially when modified with 20% glass fibre reinforcement technology. PC 5020 is such a grade developed by us, we've used this grade to make a lot of automotve parts and components for our customers worldwide.

Product Parameters

| Part Name |

Custom PC Plastic Parts Injection Molding Service |

| Mold Material |

Aluminum,45#, P20, H13, 718, 1.2344, 1.2738 and so on |

| silicon rubber Material |

NR, NBR, SBR, EPDM, IIR, CR, SILICONE, VITON,etc |

| Plastic Material |

PC/ABS, ABS, PC, PVC, PA66, POM or other you want |

| Plastic Surface finish |

Polishing finish,Texture Finish,Glossy Finish,Painting,Slik print,Rubber Painting etc |

| Drawing format |

IGES, STEP, AutoCAD, Solidworks, STL, PTC Creo, DWG, PDF, etc.. |

| The Way of Color Contrast for Plastic |

RAL PANTONE |

| Certificated |

ISO 9001:2015 Certificated, SGS Certificated |

|

Range of markets

|

industrial, consumer, food processing, aviation, seals/gaskets, lighting, packaging, filter, healthcare, telecommunications,

mechanical, water treatment, appliance, recreation, lawn and garden, educational, oil and gas, government, construction, plumbing,

surveillance, pumps,marine,motors,gears, RFID tags, electronics, and fasteners.

|

Mold Specifications

| Mold Steel |

NAK80, S136H, etc. |

| Mold Accuracy |

± 0.01mm |

| Mold Cavity |

Single or Multi Cavities as per requirement |

| Mold Life |

500k to 1.5 million Shots |

| Runner Type |

Hot Runner or Cold Runner |

| Surface Treatment |

Mirror Polishing, Texture MT, Laser Engraving, PVD Coating, Nitriding, etc. |

| Mold Equipment |

CNC, EDM, Grinding, Milling, Drilling, Wire Cutting, etc. |

| Delivery Time |

35 to 50 days |

What Kind of Part Surface Finish You Can Choose

· Metallization (chrome, gold, silver)

· Painting (hand, screen, automated)

· Vacuum plating

· Lithography

· Custom texturing

· Hydrographics

Who We Are and What We Can Do For You

We are a professional manufacturing company specialized in tooling and injection molding, locating in Shenzhen, Guangdong province of China. We've been in this industry for more than 20 years. Just give you a brief introduction of our key competencies as followed...

1. Tooling Facility. We have full set of tooling equipment among which CNC machine centre, EDM, wire cutting and mirror finishing which are state-of-the-art.

2. Injection Molding Machines. We now have 45 injection molding machines, ranging from 100 up to 800 tons, this gives us much flexibility to make any size of the product according to client's requirement.

3. Material expertise. We have used almost all types of plastic materials that exist in the world, so we're very familiar with, or exactly speaking, we're expert at plastic materials. Most of our customers appreciate and rely on our material knowledge and expertise when cooperating with us.

We have rich experiences working as a contract manufacturer for our customers worldwide, not only focusing on productions, but also, as an engineering team with strong R&D capabilities, actively taking part in the whole process of customers' programs as of below...

-Product Design: structural and functional design, material selection, PCB layout, etc.

-Prototyping

-Tooling

-Injection Molding

-Part Decoration: oil spraying, silk printing, etc.

-PCB'A for consumer electronics

-Assembly & Packaging

-Ship

With our fully-equipped facilities, well-trained people and long term experiences in the industry, we're much confidant of supplying you the product with best quality, most competitive price and fastest delivery time.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!